Get Quote for Custom Die Set

Complete this form and get a quick quote for a custom die set

This feature allows you to design and visualize your custom die set. You can see all of the parameters of your die before submitting for a quote.

Before you use this feature:

- Please first check out our large range of ready-to-ship dies in case we already make something which suits you.

- If you need a different design to what you can find here, you can just complete the form in (step 6) or send us an email with your requirements to info@pelletpressdiesets.com.

- If you want to make pellets that have a long aspect ratio (3:1 and longer) we highly recommend that you check out our Cold Isostatic Presses webpage. Under the header "What are the differences between Uniaxial pressing and Cold Isostatic Pressing" you will find more information. Please feel free to send us an email to info@pelletpressdiesets.com if you have any questions.

Live 3D Preview:

Click and drag to move the 3D model.

Click and drag to move the 3D model.

Important:

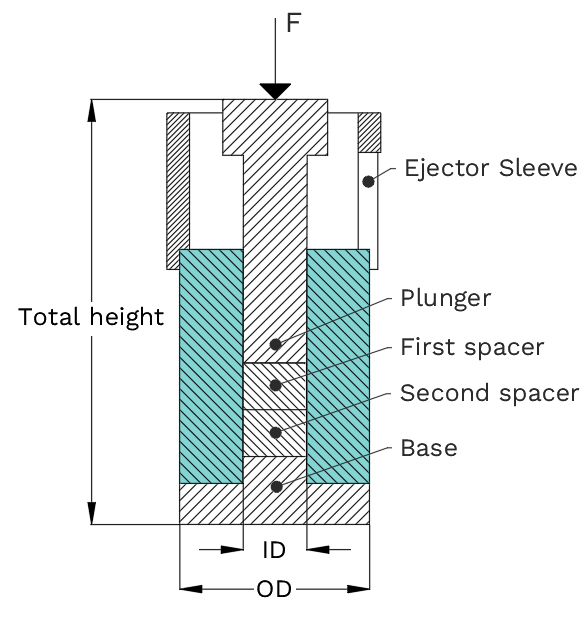

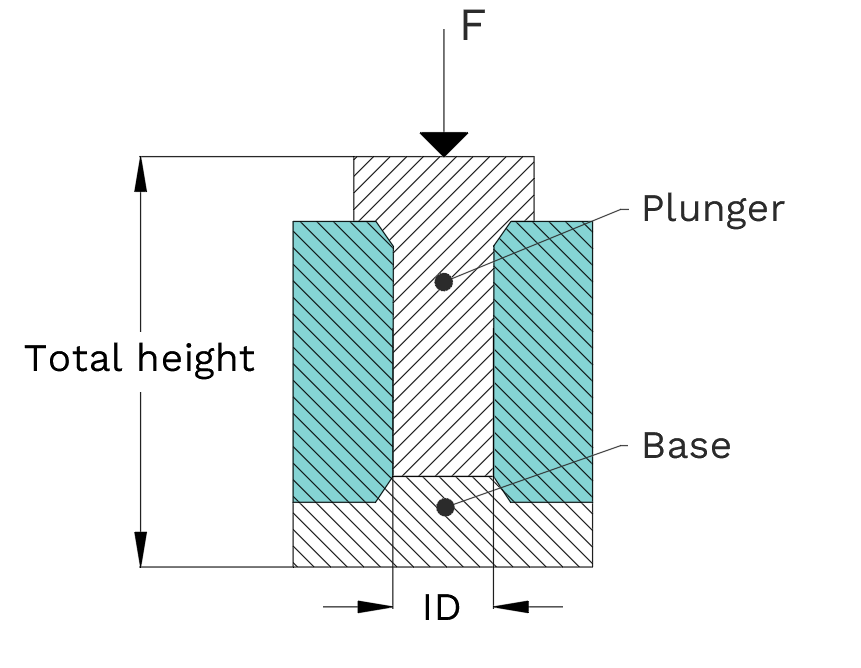

Please note that spacers and ejector sleeve are not represented in 3D model but are included in the set and in the provided pricing.

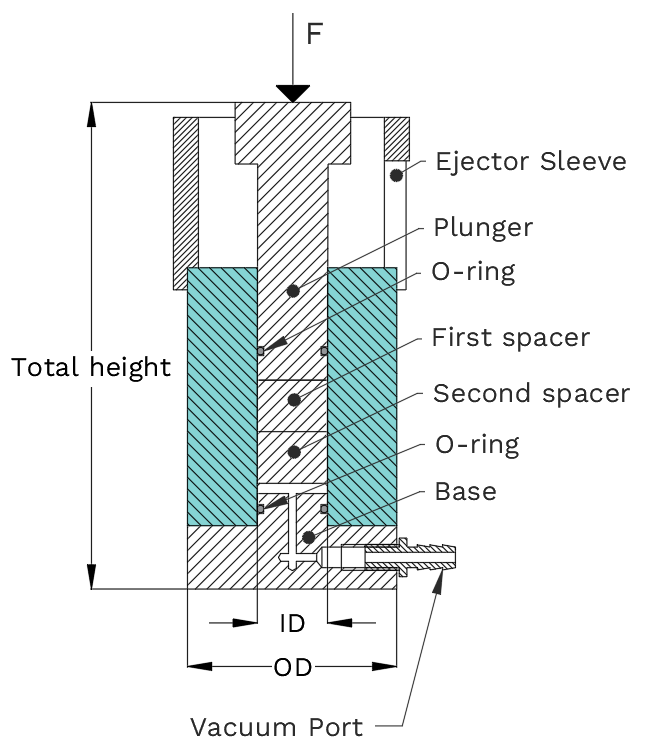

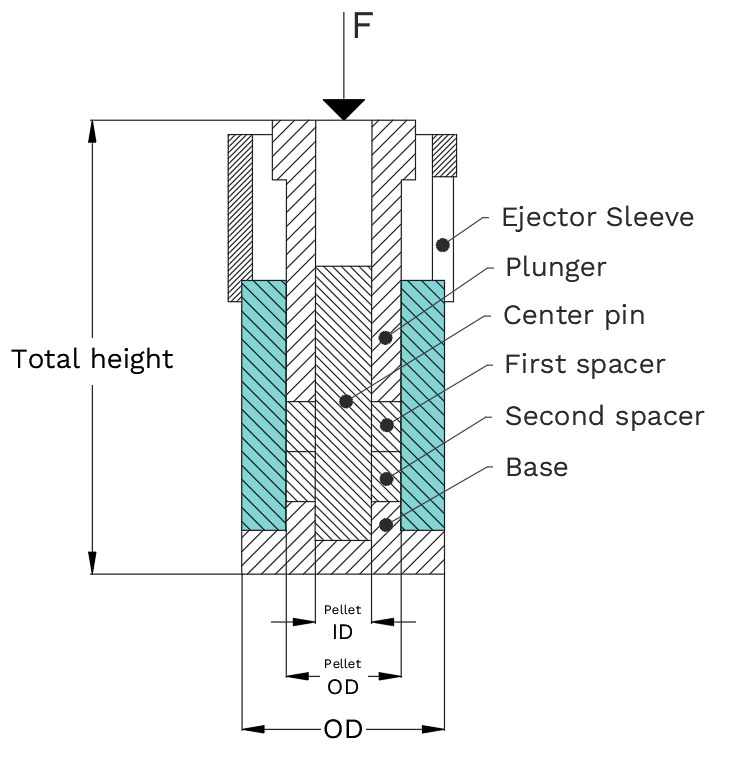

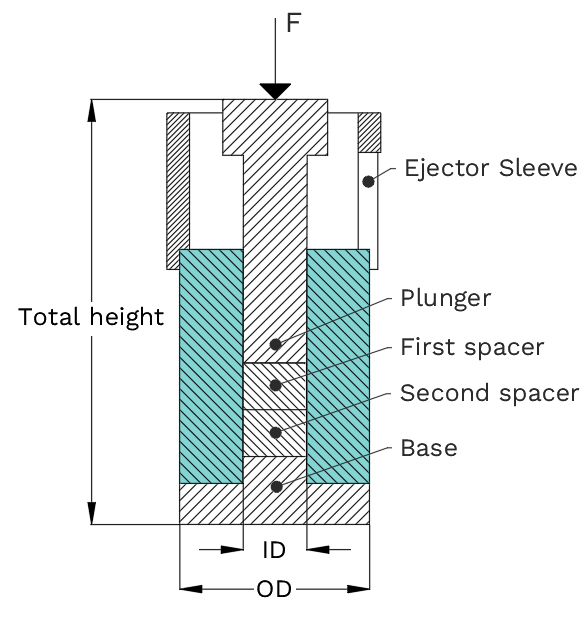

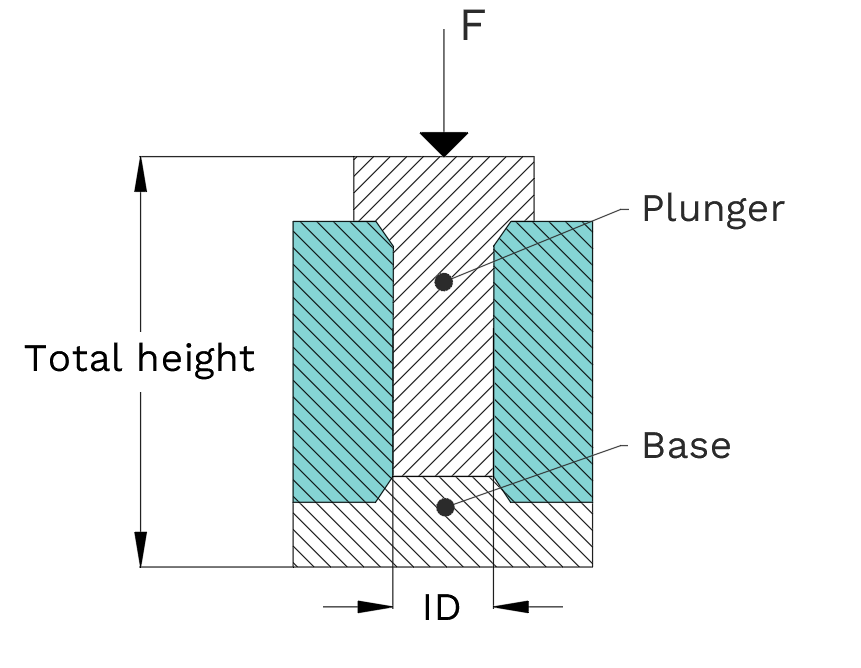

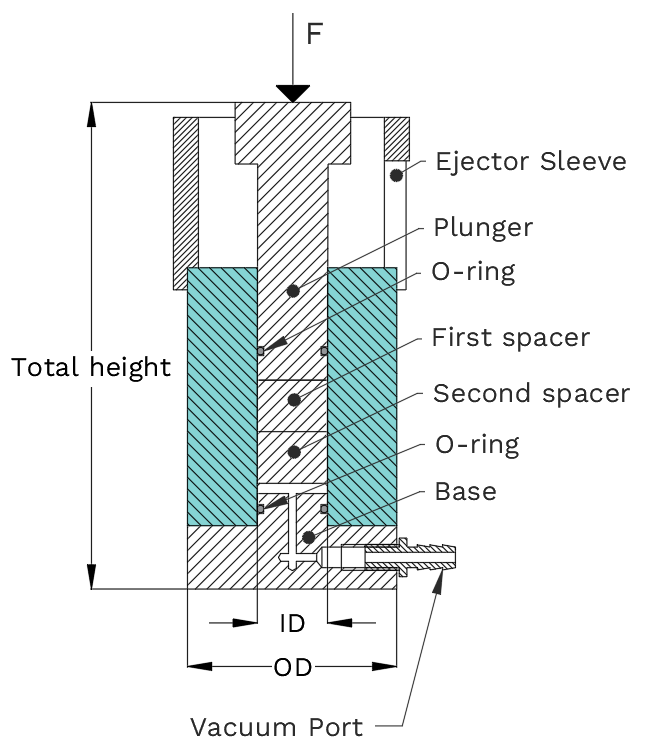

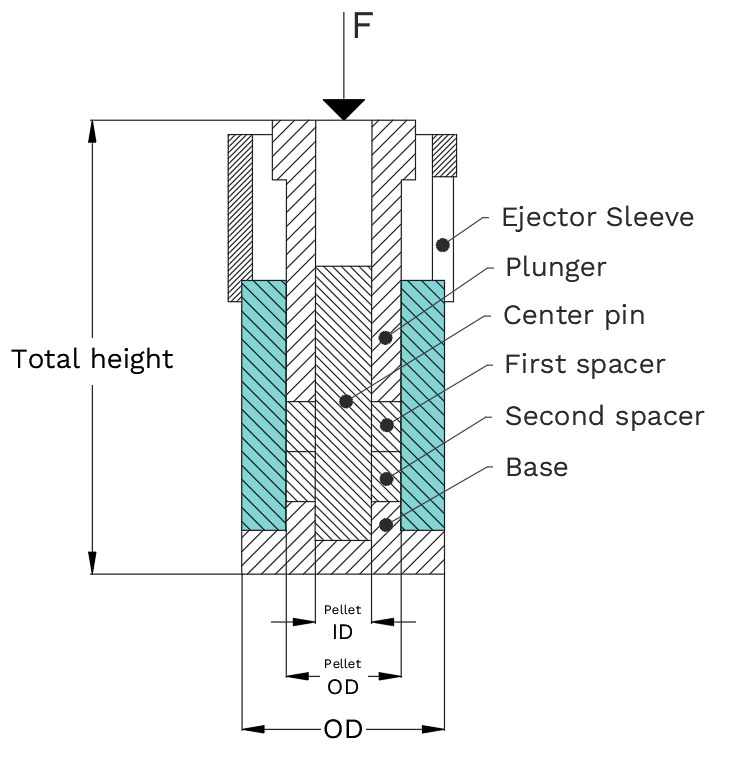

Reference Cross-Section:Please note that spacers and ejector sleeve are not represented in 3D model but are included in the set and in the provided pricing.

Step 1: Select pellet geometry

Step 2: Select material

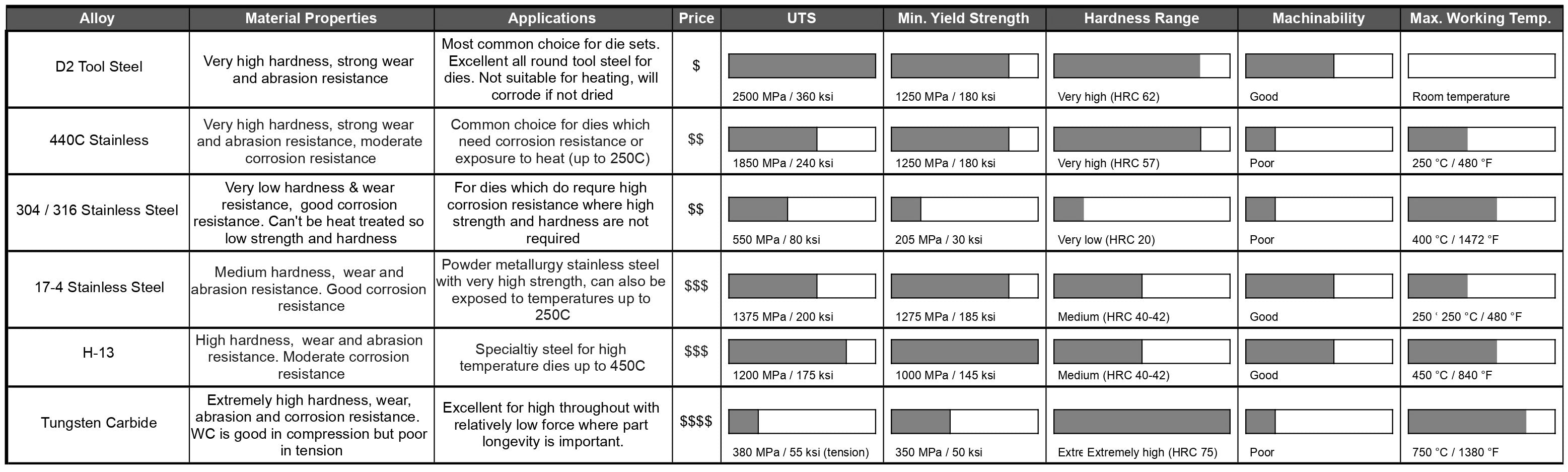

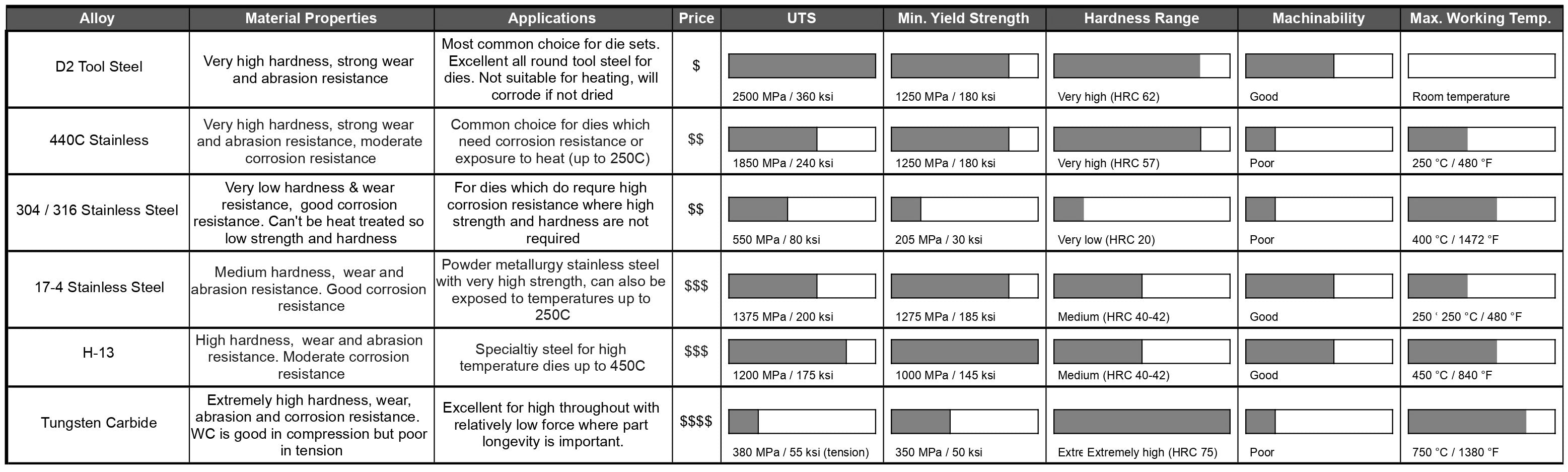

How To Choose Material?

?

Other material

Step 3: Change parameters

Units

Note: Inch allows increments of 1/16. For smaller adjustments of ID, please select mm or specify in notes.

Step 4: Check max. recommended load

?

Force

The maximum force is calculated by modelling the stresses in your custom die set, using real measured yield stresses for our high strength steel and adding in a safety margin of 50%. For the majority of cases, you can press with forces much lower than this. Never press beyond the yield strength, this can lead to catastrophic failure.

Step 5: Check technical specifications

| Material | |

| Max. Pressing Force | |

| Recommended Pressing Force | |

| Pellet Geometry | |

| Set Variant | |

| Inner Diameter (ID) | |

| Pellet Inner Diameter (pID) | |

| Inner Length (L) | |

| Inner Width (W) | |

| Outer Diameter (OD) | |

| Total Height (with spacers) | |

| Total Height (no spacers) |

Step 6: Need a quotation?

Additional comments:

Do you have any files (drawings, sketches, images) you'd like to attach? If so, please let us know in

the text field above and we'll get back to you so you can email us your files.

First name:

*

Last name:

*

Email address:

*

Phone:

*

Institution / Company:

*

Street address:

*

Address line 2:

City:

*

State / Province / County:

*

Postal / Zip Code:

*

Country:

*

Material Information Sheet: